Your Trusted Partner in Ultrasonic Inspections Australia-wide

Protecting Your Assets Is Our Focus.

Highpoint Solutions provide airborne ultrasonic inspection services throughout Australia. With offices on the Sunshine Coast and Brisbane, we regularly service rural and remote areas throughout Queensland.

Airborne ultrasonic inspections are ideal for conducting; compressed air leak surveys, gas leak detection, steam trap surveys, condition monitoring of bearings, electrical inspections, identifying bearing lubrication issues, and un-pressurised leak detection.

The Advantages of Ultrasonic Surveys are Clear.

Ultrasound from an ultrasonic survey is very directional and can be easily blocked or shielded.

Ultrasound from an ultrasonic survey instrument can be used in noisy environments.

Changes in the ultrasonic signature provide an early warning of potential problems or hazards.

Ultrasonic scanning performed by our experienced ultrasonic technicians provide another valuable tool for your preventative and predictive maintenance programs.

How We Add Value To Your Business Using Ultrasonic Equipment.

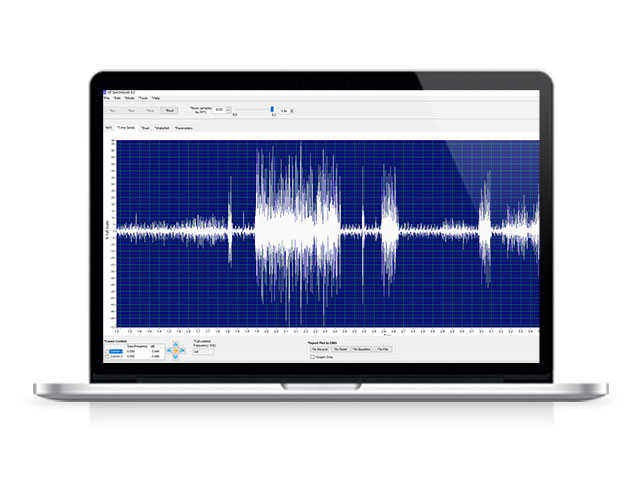

We use state-of-the-art airborne ultrasound equipment to identify; electrical faults, mechanical faults, compressed air leaks, and bearing lubrication issues, allowing you to take corrective actions to minimise damage to plant/equipment and decrease repair costs. We'll physically show you what you can't hear!

Saving time – One of the many benefits of ultrasonic inspections is there’s no down-time required. Our non-destructive, non-intrusive inspection methods allow your daily operations to continue unaffected by our work.

Ultrasound inspection is a valuable tool for predictive and preventive maintenance, energy management and quality control.

Periodic monitoring of plant and equipment allows us to establish trends which are used to predict equipment failure. This invaluable data allows your preventative maintenance team to carry out upgrades and maintenance tasks in a “planned” window, rather than an unplanned outage resulting in a loss of revenue and production.

Ultrasonic Inspections For Compressed Air Leak Detection

Since air leaks are almost impossible to see, other methods must be used to locate them. The best way to detect leaks is to use an ultrasonic acoustic air leak detector, which can recognize the high frequency hissing sounds associated with air leaks. These portable leak detectors units consist of directional microphones, amplifiers, and audio filters, and usually have either visual indicators or earphones to detect leaks.

Why carry out compressed air leak detection within you work place or factory? These leaks can be a significant source of wasted compressed air energy within your compressed air system, in some cases wasting unto 20-30% of a compressor's output. A typical plant that has not been well maintained will likely have a leak rate equal to 20% of total compressed air production capacity. On the other hand, proactive leak detection and repair can reduce leaks to less than 10% of compressor output.

As well as a source of wasted energy, compressed air leaks can also contribute to other losses. These could include a drop in system pressure, which can make production equipment function less efficiently, adversely affecting production, shorten the life of components within the air compressors as well as adding additional run hours to your equipment, leading to more frequent servicing costs.

A good air leak prevention program will include the following components: identification, photographing (and tagging), verification severity of the leak, and calculate the annual cost. Highpoint Solutions can assist by providing an Ultrasonic Air leak prevention program should you be looking at not only reducing the overall run costs associated with your compressed air system but improve the efficiency, reliability, stability and cost effectiveness of your compressed air system.

Airborne ultrasound surveys WILL save you money and unplanned downtime.

Highpoint Solutions offers electrical inspections using ultrasound testing at all voltages; low, medium and high voltages that can help prevent equipment failure and avoid costly downtime. Ask us about our electrical thermography services.

Combine ultrasound & infrared thermography for enhanced data reliability.

Airborne ultrasound is used extensively for condition monitoring, energy conservation and quality assurance programs in mechanical plants, throughout the world. Infrared thermography is the perfect partner for ultrasonic inspection.

Highly accurate & reliable data packaged into an easy to digest and detailed report.

On completion of our ultrasonic inspection, we will produce a detailed report within 24hrs!

We offer a nationwide service and can be on site at most places throughout Australia within 48hrs from initial contact.