7 Key Benefits Of Thermal Imaging Technology

Benefits of Thermal Imaging Technology

Thermal imaging technology is used in a diverse range of applications in many industry sectors. There is an endless list of benefits of utilising thermal imaging in predictive maintenance and condition monitoring (CM), however the key benefits include:

- Zero to minimal down-time: Due to the non-contact and non-invasive nature of thermal imaging, thermographers can carry out thermal analysis inspections while the plant or equipment is still fully operational.

- It saves our clients money: Thermal imaging can detect faulty components or systems at an early stage, thus allowing the company to plan and conduct remedial work within a scheduled maintenance window. By early fault detection, damage to vital operational systems may be avoided saving thousands of dollars in unexpected down-time.

- Accuracy and speed: Thermal imaging surveys can quickly scan and measure the temperature distribution of entire surfaces of electrical and mechanical equipment under normal load conditions, eliminating the need for pre-inspection work and lengthy preparation.

- 100% non-invasive: Thermal imaging cameras (or infrared cameras), are passive instruments meaning they detect infrared energy emitted of the subjects surface. This passive and non-invasive approach ensures the thermographer can maintain a safe distance from the potentially hazardous equipment. Furthermore, there is no potential for damage to occur to the systems or equipment as a result of the thermal survey.

- Significantly reduces the risk of Occupational Health & Safety issues in the workplace: Intervention through early detection can prevent hazardous equipment failure, personal harm, and risk of fire. As an added bonus, and depending on your insurance policy, you may also be eligible for a discount in your insurance premiums.

- It has revolutionised predictive maintenance inspection programs: By detecting problems and scheduling repairs before a major failure occurs, productivity, profitability and workplace safety are all increased.

- Infrared Thermography meets Risk Compliance: Thermographic surveys support the processes involved in regulatory compliance with Health and Safety Legislation while meeting insurance specified risk assessment and prevention criteria.

What is Thermography?

Thermography is a non-invasive diagnostic method, based on object surface temperature detection. The infrared (IR) radiation emitted from an object is recorded and visualised in the form of a temperature distribution map. The resulting image, known as a "thermogram", can be used to determine; structural defects, electrical faults, mechanical faults, physiological changes in people & animals, and much more.

Condition Monitoring

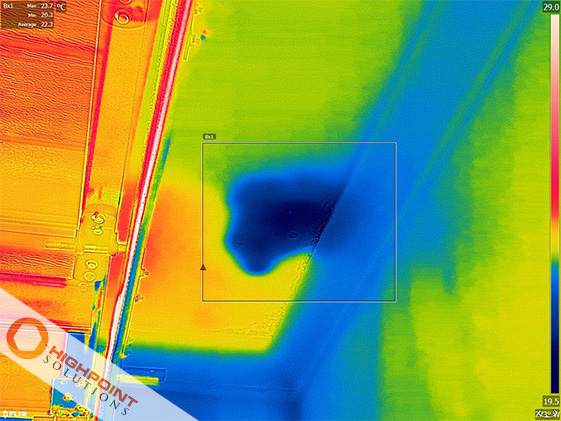

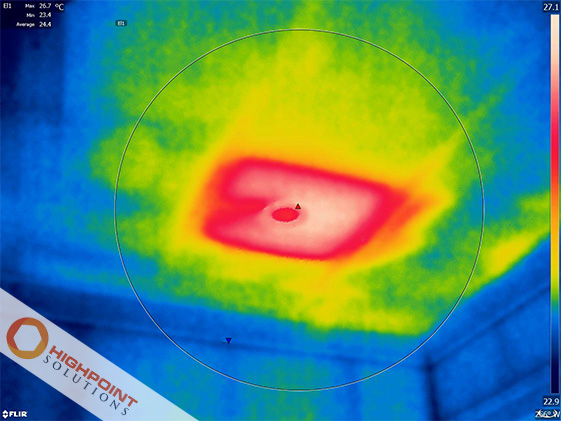

Condition Monitoring Water Leaks

Water Leaks Ineffective Insulation

Ineffective Insulation Plumbing Leaks

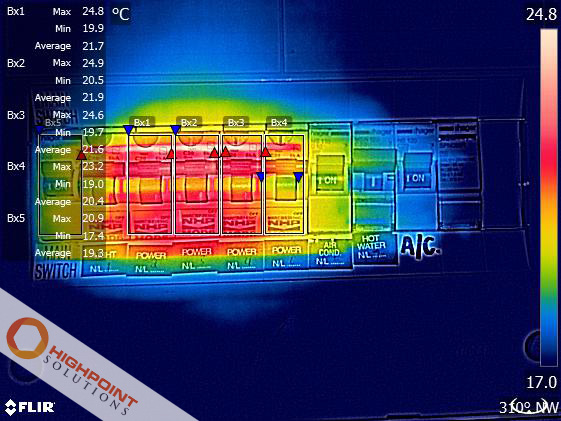

Plumbing Leaks Electrical Fault Detection

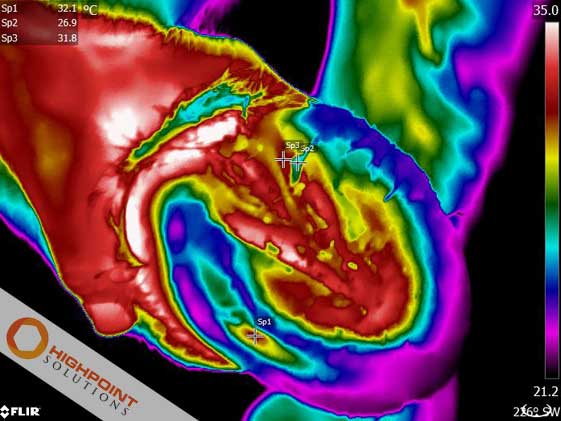

Electrical Fault Detection Equine Thermography

Equine Thermography

Why use Highpoint Solutions?

Highpoint Solutions provides superior “independent” thermography and rope access services. We are an inspection and maintenance company with many years experience in the industry. We pride ourselves on being locally owned, so you can expect a far superior service compared to that of a nationwide chain company.

We specialise in accurate thermography inspections that deliver the data you can rely on. Our rope access capabilities allow us to quickly and safely access hard to reach areas such as high-rise buildings and other structures without disturbing or disrupting occupants of the building.

At Highpoint Solutions, our Integrated Safe Systems of Work (ISSOW) protocol has ensured that we have maintained an Incident and Injury Free (IIF) status.

Maximise Production

Producing faster, better, more efficiently and at a lower cost. In order to reach these goals, industrial plants need to be running continuously: 24 hours a day, 365 days a year. Our Condition Monitoring services are designed to ensure maximum equipment uptime.

Proactivity - Key to Success

A proactive approach allows identification of warning signs and potential issues which can prevent early component failures. Optimum maintenance scheduling through the use of proactive Condition Monitoring (CM) is a key factor to your businesses success!

Predictive Maintenance

Where temperature is a key factor, IR Thermal Imaging is one of the best tools for predictive maintenance. Make Predictive Maintenance a key tool in your asset management plan.

REDUCING UNPLANNED DOWNTIME = HIGHER COST SAVINGS! = HIGH PROFITABILITY!