Thermography For Building Diagnostics

Building inspections using thermal imaging

Inspecting buildings using a thermal imaging camera is a powerful and non-invasive means of monitoring and diagnosing the condition of buildings. Thermal imaging technology is one of the most valuable diagnostics tools for building inspections. Using thermal imagery, we can identify problems early, allowing them to be documented and corrected before becoming more serious and more costly to repair.

A building diagnostics inspection with a thermal camera can help:

Visualise energy losses

Detect missing or defective insulation

Source air leaks

Find moisture in insulation, in roofs and walls, both in the internal and the external structure

Detect mould and badly insulated areas

Locate thermal bridges

Locate water infiltration in flat roofs

Detect breaches in hot water pipes

Detect construction failures

Find faults in supply lines and district heating

Detect electrical faults

Flood and Moisture Assessments

Moisture intrusion or leaks within buildings can not only cause damage to the buildings but can also lead to a health hazard for the occupants due to mould growth.

Insulation problems, water intrusion and ineffective ventilation can all cause moisture and mould growth. A thermal imaging survey can detects these problems and provide you with visual evidence of the locations and extents of the problems.

What you see.

What we see - Moisture damage in ceiling

Electrical Surveys

Electrical surveys can identify poor connections, overloaded circuits, failing components or imbalanced loads. Any faults on electrical systems are expensive in terms of plant downtime, damage, loss of production or risk from fire.

Poor electrical connection on the main supply fuse.

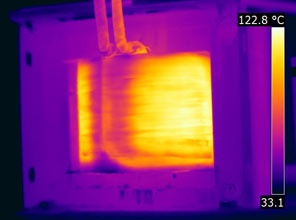

Over heating windings on an air cooled transformer.

Building Heat Loss Surveys

We often conduct heat loss surveys for private clients who find that their heating costs have soared or who have a particular concern with a room, extension or the whole house. We can carry out a survey on your home or property and produce a report which will clearly identify heat loss or energy wastage. Very often the problems are not what the home owner thought they would be.

Air leak around outlet.

Cold air leak at doorway.

Missing or Ineffective Insulation

Missing or inadequate home insulation can literally cost you hundreds each year in additional power usage. By inspecting your property through the eyes of a thermal imaging camera, we are able to easily locate building defects and areas where insulation is defective or not even there at all.

We have developed an inspection procedure for residential properties and commercial premises which allows us to survey a property both internally and externally to highlight heat loss and energy wastage. We will carry out the survey and produce a clear professional report within 4 working days.

Insulation missing within wall cavity (above)

Hot air leakage in the roof soffits

Termite and Pest Discovery

"If you haven't seen thermal, you're only seeing half the picture".

In Queensland’s climate, an infestation of either vermin, insects or termites are common concerns which can cause thousands of dollars in damages, destabilise the structural integrity of your property, de-value resale prices and potentially cause harm to your family.

We use thermal imaging cameras to successfully locate termites in buildings in a non-destructive manner. Some advantages of using a thermal imaging camera to locate termites include:

- Rapid an effective scanning for termites

- Non-destructive

- Environmentally friendly

- Thermal images provide evidence and proof of infestation

- Scans all areas, walls, floors, ceilings, and outdoor areas

- No radiation used

- No damage to the building

- Accurately locates where to place chemicals for best effect

Possum in roof

Termite packing inside internal wall

"We Defeat Pests at Hide-&-Seek with FLIR Thermal Imaging Cameras."

Thermography for Industrial Applications

High Voltage Surveys

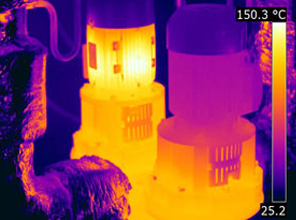

Heat is an important factor in high voltage installations. When electrical current passes through a resistive element, it generates heat. An increased resistance results in an increase in heat. Over time the resistance of electrical connections will increase, due to the loosening and corrosion for instance. The corresponding rise in temperature can cause components to fail, resulting in unplanned outages and even injuries. In addition, the energy spent on generating heat causes unnecessary energy losses. If left unchecked, the heat can even rise to a point where connections melt and break down; as a result, fires may break out.

Examples of failures in high-voltage installations that can be detected with thermal imaging include:

Oxidation of high voltage switches

Overheated connections

Incorrectly secured connections

Insulator defects

We can spot these and other issues at an early stage with a thermal imaging camera. We will help you accurately locate the problem, determine the severity of the problem, and establish a time frame in which the equipment should be repaired.

A wide view of a substation can quickly show areas where unwanted high resistance connections exist.

No other predictive maintenance technology is as effective for electrical inspections as thermal imaging.

Low Voltage Surveys

Electrical cabinets and motor control centres are regularly scanned with a thermal imaging camera. Besides loose connections, electrical systems suffer from load imbalances, corrosion, and increases in impedance to current. By conducting a low voltage survey using a thermal imaging camera we can quickly locate any hot spots and determine the severity of the problem.

Examples of failures in low voltage equipment that we can detect with thermal imaging include:

- High resistance connections

- Corroded connections

- Internal fuse damage

- Internal circuit breaker faults

- Poor connections and internal damage

We can conduct low voltage power surveys in production plants, office facilities, hospitals, airports, hotels or domestic residences. Take a look at just a few illustrations of how we use thermal imaging cameras to identify dangerous situations.

Thermal imaging surveys are non-invasive and non-destructive allowing the thermal imaging survey to be completed whilst plant and equipment is running.

All surveys are quantified by a fully comprehensive report, detailing our findings and recommendations for the repair of any fault.

Overheating terminal (above/below).

Thermography for Mechanical Installations

In many industries, mechanical systems serve as the backbone of operations. Thermal data collected with a thermal imaging camera can be an invaluable source of complimentary information to vibration studies in mechanical equipment monitoring.

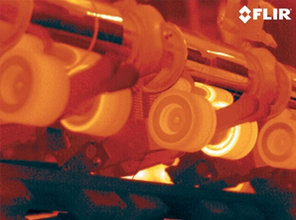

Mechanical systems will heat up if there is a misalignment at some point in the system. Conveyor belts are a good example of this. If a roller is worn out, it will clearly show in the thermal image so that it can be replaced.

Typically, when mechanical components become worn and less efficient, the heat dissipated will increase. Consequently, the temperature of faulty equipment or systems will increase rapidly before failure. By periodically comparing readings from a thermal imaging camera with a machine's temperature signature under normal operating conditions, we can detect a multitude of different failures.

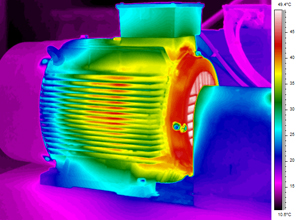

Motors can also be inspected with thermal imaging cameras. Motor failures like brush contact-wear and armature shorts typically produce excess heat prior to failure but remain undetected with vibration analysis, since it often causes little to no extra vibration. Thermal imaging gives us a full overview and allows us to compare the temperature of different motors.

Other mechanical systems we monitor with thermal imaging cameras include; couplings, gearboxes, bearings, pumps, compressors, belts, blowers and conveyor systems.

Pipework

Thermal imaging gives valuable information about the condition of the pipe, tube and valve insulation. Inspecting the condition of the insulation material surrounding the pipework can be crucial. Heat losses due to failing insulation and cladding will show up very clearly within the thermal images we take, allowing you to quickly repair the lacking insulation and prevent significant energy losses or other damages.

Process valves are another good example of pipework related equipment that we can inspect with a thermal imaging camera, Besides leakage detection, we can also tell whether the valve is opened or closed, even from a distance.

Examples of pipework faults that can be detected with thermal imaging are:

- Leakage in pumps, pipes and valves

- Insulation breakdowns

- Pipe blockages

Steam trap identified in valve.

Insulation damage.

All types of leakage, blocked pipes and faulty insulation will clearly show up on the thermal image. And because a thermal image can quickly give you an overview of an entire installation, there is often no need to check each pipe individually.

Our IRATA Certified Rope Access Technicians Take on the Biggest Jobs!

Our IRATA Certified Rope Access Technicians Take on the Biggest Jobs!

Our full suite of services includes

Specialist Rope Access Solutions

Thermal Imaging Surveys

Mechanical Installation Thermography

Corrosion Under Insulation (CUI) Thermographic Evaluations

Electrical Thermography

Infrared Leak Detection

Predictive Maintenance

Renewable Energy Thermographic Surveys (Wind and Solar Systems)

Services overview

Rope Access Services

Access the usually inaccessible places by using our rope access services. From highrise building maintenance to telecommunications towers or refineries, our IRATA certified Rope Access Technicians are up for the most challenging jobs.

Repair works

Preservation of sealed/caulked joints or interfaces is a crucial aspect of on-going building maintenance. The consequences of failed sealant joints can be structurally and economically catastrophic.

High Voltage Inspections

The multitude of possible applications for thermal imaging cameras within the range of electrical systems can be divided into two categories: high voltage and low voltage installations.