3 Ways Infrared Thermography Improves Electrical Maintenance

In many commercial and industrial facilities, an essential but often overlooked asset is the electrical system. Without electricity, it's likely that most production facilities could simply not operate. Almost everything runs on electricity, however once installed and running smoothly it is usually forgotten until either something goes up in smoke, equipment breaks down, or worst-case results in a fire outbreak.

Traditionally, electrical maintenance consists of either;

1. Routinely replacing old components for new after a predetermined period. Not only is this expensive but it's just plain wasteful! or;

2. Taking a re-active approach and replace faulty components or systems only once they fail. This is usually very expensive due to the excessive production downtime.

Both scenarios are far from ideal. Fast-forward to modern day predictive maintenance and condition monitoring practices and we have an inspection method that is truly unrivalled - Infrared Thermography.

Before we dive in explore how infrared thermography can improve electrical maintenance, let's take a quick look at what is infrared thermography actually is.

In a nutshell, Infrared thermography is the science of detecting infrared energy emitted from an object, converting it to apparent temperature, and displaying the result as an infrared image. Literally, infrared thermography means “beyond red” (infrared) “temperature picture” (thermography). Infrared thermography is a non-contact, non-invasive and non-destructive inspection method which is being heavily implemented in condition monitoring programs around the world. The non-contact nature of infrared thermography makes it ideal for a wide range of applications where components are moving, very hot, dangerous to contact, difficult to reach, impossible to shut off, or could be contaminated or damaged through contact.

So... how can infrared thermography improve electrical maintenance?

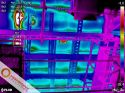

Infrared thermography is an inspection method that shows a thermographer (in real-time) the heat distribution of an object. Due to the extremely hazardous nature of electricity, and the non-contact method of inspection, infrared thermography is an ideal solution for scanning electrical switchboards and switch-gear to identify faulty equipment which usually present in the form of "hot-spots". During an electrical infrared inspection, the thermographer is looking for unusual temperature differentials and thermal patterns referred to as "anomalies". Thermal anomalies and hot-spots are often the result of; loose electrical connections, damaged wiring or components, faulty circuit breakers, unbalanced or overloaded circuits, poor performing fuses and more. If a commercial or industrial establishment are looking to take their preventative maintenance program to the next level, then here are 3 ways infrared thermography can make it happen.

1. Infrared thermography is non-contact.

Unlike other inspection methods that require physical contact with the target such as vibration analysis or ultrasonics, infrared thermography is 100% non-contact. This dramatically reduces the risk of potential injury to the maintenance electricians. Using the highest level from the Hierarchy of Hazard Control, we "eliminate" the need to touch equipment during an inspection. Infrared thermography is an ideal diagnostic tool that can assist in troubleshooting electrical components like blown fuses and tripping circuit breakers. Rather than replacing a whole piece of electrical equipment, an infrared inspection could pin-point the problem down to a minor component replacement or simply a loose connection as is often the case.

2. Infrared thermography can be easily integrated into an existing preventative maintenance program.

Another way infrared thermography can improve electrical maintenance is to incorporate routine thermographic inspections into an existing preventative maintenance or condition monitoring (CM) program. Preventative maintenance is an important part of facilities management. The goal of a successful preventative maintenance program is to establish consistent practices designed to improve the performance and safety of the equipment. Moreover, the planned maintenance of equipment will help to extend equipment lifecycles and avoid any unplanned maintenance activity. A successful preventative maintenance program is dependent on the combined efforts and cooperation of all the parties involved. For this reason, engineering managers must rely on the knowledge, ideas, and contributions of all the maintenance personnel.

The predictive nature of infrared thermography is due to the fact that infrared cameras are capable of detecting and tracking heat in components and wiring which is usually the cause of electrical failure in equipment. There are basically two options to incorporate infrared thermography into a preventative maintenance program. One option is to purchase your own infrared camera, receive accredited training through an infrared training centre, and create your own infrared inspection program in house. Due to the high capital expenditure of purchasing your own infrared camera, and the level of training required to be considered competent for the task, buying your own IR camera and conducting your own thermographic inspections is not advised. The second option is to hire an infrared inspection company, such as Highpoint Solutions, and have experienced thermographers handle the inspection and comprehensive reporting for you. Unfortunately, experience is one thing you can't get for nothing.

3. Infrared thermography validates return on investment (ROI).

The third, and by no means the last way that infrared thermography improves electrical maintenance is by validating the ROI of the maintenance program itself. When conducted by an experienced inspection company such as Highpoint Solutions, and repairs are rectified within an acceptable timeframe, thermographic inspections can provide a cost savings ratio of 4:1. The reason the ROI ratio is so beneficial to the facility is because thermographic inspections identify problems "before" they result in equipment failure and plant downtime. By identifying and flagging suspect equipment, repairs can be made in a planned maintenance window which minimises financial losses from lack of production.

Once installed and commissioned, electrical systems are generally very reliable and robust, however they still do require periodic maintenance. For this reason, electrical maintenance programs are enforced to protect plant, equipment, and personnel while prolonging asset lifecycles. Creating a highly efficient and cost effective electrical maintenance program that falls within budget is easier said than done, however due to advances in modern technology infrared inspection companies are now able to inspect significantly more equipment in shorter timeframes. Do maintenance managers and inspection engineers find infrared thermography a viable solution for improving electrical maintenance? You bet they do!

Learn more about our electrical thermography services by calling our team on: 1300 851 842

Recent Posts