10 Benefits of Utilising Rope Access for Building Maintenance & Construction

When it comes to working at heights or hard to access areas, rope access is by far the safest and most efficient access method used around the world today!

You may be thinking "That's a big call!"

Well the facts are... due to the evolution of rope access equipment, safe systems of work, and the high level of training technicians endure to get their certification, the rope access industry has seen the lowest incident and injury rate in the entire access industry!

At Highpoint Solutions, our rope access technicians are able to perform inspection and maintenance tasks utilising specialised access techniques. Just some of the capabilities include;

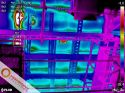

- Thermal imaging building diagnostics (I.e. Water leaks, moisture ingress, electrical faults, delaminated render, air leaks in windows/frames etc.)

- Building/Plant construction

- Structural steel installation

- Electrical and mechanical installations

- CVI's (close visual inspections) and Infrared Imaging of building facades

- Painting, caulking, window cleaning, and glass restoration

- Waterproofing

- Signage installation

- and more.

It has become a well-established fact over the past few decades that rope access is the best option for carrying out a multitude of tasks at heights. Utilising specialist rope access techniques for maintenance & inspection work allows our clients to reap the benefits from the delivery of cost effective and efficient solutions that help them minimise down-time and ultimately increase profits.

So what exactly are the benefits of rope access?

Well, there are many benefits speaking for rope access. Unlike traditional access methods such as scaffold, scissor lifts, elevated work platforms and so forth, custom rope access solutions can be designed to fit various applications. Among other benefits, rope access is:

- Cost-effective - As stated, rope access services are very economical. Fewer personnel can accomplish more tasks sooner which translates to minimal downtime, increased production, and increased profits for our clients.

- Versatility - Our IRATA certified rope access technicians can apply technical rope access techniques to a wide variety of environments; from confined space scopes, to complicated structural steel installations.

- Environmentally friendly - Rope access techniques leave a minimal footprint on the surrounding environment compared to traditional methods. We don't require petrol, oil, or electricity to access even the highest or tightest areas.

- Fast & Efficient - Rope access systems are established and dismantled very quickly compared to traditional access methods. Less interference with other facility operations means less disruptions, minimised downtime, and a safer work environment for all personnel.

- Safety - Our IRATA certified rope access technicians uphold an exceptional safety record which has resulted in our work being classed as one of the safest in the whole construction industry. We place a high focus on the identification and implementation of dropped object controls, safe systems of work, rope access rescue plans and other procedures to maintain our incident & injury free status. We don't compromise safety!

- Unobtrusive - Utilising rope access can provide an unobtrusive, cost effective access capability.

- Reduced Man Hours - When comparing rope access to traditional access methods, the man hours required to complete the same task are significantly reduced.

- Superior Access - Rope access systems can be quickly established to reach almost any area you could imagine. This is literally impossible with other traditional access methods. Rope access methods can be used to access structures or areas that would not otherwise be possible to reach via conventional methods. The internals of industrial chimneys & smoke-stacks, domed roofs, and ducting all require maintenance at some point in time of which rope access is the preferred method.

- Flexibility - Greater flexibility and rescheduling can be achieved using rope access. A change in weather conditions or changing work priorities can be easily accommodated with rope access. The hire and transportation of traditional access equipment such as Elevated Work Platforms (EWP's) or scaffold can quickly become a logistical or financial nightmare if work priorities change at short notice.

- Eliminate the Need for Heavy Equipment - The unobtrusive nature of rope access systems minimise the disruption on the ground, therefore allowing workers below to carry out their daily duties. This is not the case with heavy equipment and scaffolding. Generally speaking, erecting scaffold to access high areas requires much more manpower and time. There is also a significant increase in hazards associated with erecting scaffold including dropped objects which have the potential to be fatal.

Highpoint Solutions is capable of effectively utilising rope access methods to perform a wide variety of maintenance and inspection work. If you'd like to learn more about our rope access capabilities and how we can serve your company on the most cost effective and efficient manner, call us today on 0407 202 064.

Recent Posts